Groundnut is an important oil seed crop in Krishnagiri and cultivated in area of

10,037 hectares & with a production of 2.1 lakh qtl. The productivity of groundnut

in the district is 20.97 qtl per hectare under irrigation while it is 15.2 qtl per

hectare under rainfed conditions.

Traditional methods of field operations require huge number of labour and more time,

ultimately lead to increase in cost of cultivation. Acute shortage of labour is

experience now a days during field operations due to increased industrialization and

other opportunities for labour like migration of labour to urban areas for

better-paid employment coupled with policy changes like implementation of MGNREGA

has made a profound impact on labour availability in the rural areas. In addition,

labour shortage problems are being faced by farmers during peak seasons and labors

are available at a higher cost.

To overcome the shortage of labour and to perform the field operations at right time

and to take the advantage of favorable climatic conditions, the farmers can go for

farm mechanization by the use of efficient and improved tools, equipment and

machines suitable to the soil conditions for groundnut crop cultivation. ‘Farm

mechanization’ implies the use of various power sources and improved farm tools and

equipment, with a view to reduce the drudgery of the human beings and draught

animals, enhance the cropping intensity, precision and timelines of efficiency of

utilization of various crop inputs and reduce the losses at different stages of crop

production. Therefore, there is a greater need to adopt new farm machinery or to

improve the existing farm machinery in groundnut cultivation. For every cultural

operation under groundnut, the scientists have developed different farm implements

but their reach into the farming communities was found to be very sparse. Hence, KVK

decided to extent of awareness, knowledge and adoption of different farm machinery

by the farming community in groundnut cultivation and proposed a Front-Line

Demonstration on “Farm Mechanization in Groundnut cultivation” during 2019-20.

Plan, Implement and Support:

The demonstration was conducted in 10

farmers filed at Valluvarpuram village of Krishnagiri taluk. The following machines

were demonstrated during FLD.

1. Hand operated decorticator:

Hand operated groundnut decorticator can be used to shell groundnut pods and

to separate kernels.

It consists of and oscillating sector with sieve bottom and a handle.

Number of hard rubber or cast-iron lined assemblies is fitted in the oscillating

sector unit. The groundnut pods are shelled between the oscillating sector and

the fixed perforated concave screen by rubbing action. The decorticated shells

and kernels fall down through the perforated concave sieve. The kernel and

shells are collected at the bottom of the unit and separated manually. Clearance

between the concave and oscillating sector is adjustable to suit the different

varieties and concave sieves are also replaceable depending upon the pod size.

Its overall dimensions are 600 X 350 X 700 mm. the capacity and efficiency of

the unit are 50 kg/ha and 98% respectively.

Number of hard rubber or cast-iron lined assemblies is fitted in the oscillating

sector unit. The groundnut pods are shelled between the oscillating sector and

the fixed perforated concave screen by rubbing action. The decorticated shells

and kernels fall down through the perforated concave sieve. The kernel and

shells are collected at the bottom of the unit and separated manually. Clearance

between the concave and oscillating sector is adjustable to suit the different

varieties and concave sieves are also replaceable depending upon the pod size.

Its overall dimensions are 600 X 350 X 700 mm. the capacity and efficiency of

the unit are 50 kg/ha and 98% respectively.

2. Tractor drawn seed cum fertilizer drill:

Tractor drawn groundnut seed cum fertilizer drill 9 row tractor operated

groundnut seed drill with row to row spacing of 30 cm fir timely sowing with

mechanical advantage and intercropping fertilizer facility is provided. This is

provided with a hopper and seed metering mechanism as the main components. The

hopper is divided into boxes each can accommodate 5 kg of seed (total 40 kg).

The inclined plate seed metering mechanism gives correct seed to seed distance

of 10 cm in a row and maintains the recommended seed rate of 100 kg/ha with

optimum plant population of 33 per square meter area. Placement of seed is at

proper depth of 4 - 5 cm. the seed damage is negligible and the field capacity

is 6 to 7 ha/day and facilitates coverage of large area before the soil moisture

is dried up. A 5 cm width covering blade is also attached behind the furrow

openers to cover the furrows opened after seed placement. The intercropping of

redgram or castor can also be possible using Anantha planter along with

groundnut sowing. The spring type cultivator frame of this planter facilitates

to work even in stony soils.

Tractor drawn groundnut seed cum fertilizer drill 9 row tractor operated

groundnut seed drill with row to row spacing of 30 cm fir timely sowing with

mechanical advantage and intercropping fertilizer facility is provided. This is

provided with a hopper and seed metering mechanism as the main components. The

hopper is divided into boxes each can accommodate 5 kg of seed (total 40 kg).

The inclined plate seed metering mechanism gives correct seed to seed distance

of 10 cm in a row and maintains the recommended seed rate of 100 kg/ha with

optimum plant population of 33 per square meter area. Placement of seed is at

proper depth of 4 - 5 cm. the seed damage is negligible and the field capacity

is 6 to 7 ha/day and facilitates coverage of large area before the soil moisture

is dried up. A 5 cm width covering blade is also attached behind the furrow

openers to cover the furrows opened after seed placement. The intercropping of

redgram or castor can also be possible using Anantha planter along with

groundnut sowing. The spring type cultivator frame of this planter facilitates

to work even in stony soils.

3. Tractor drawn inter-cultivation implement:

A 8 row tractor operated inter - culture implement used for weeding in groundnut

crop was demonstrated.

Its frame is provided with 8 tynes each tyne attached with T or V - shape sweeps

to work in between 30 cm row spacing of the crop without any plant damage. Two

small width pneumatic tyres of 8.3 X 28” size need to be fitted to the rear axle

of the tractor to run in between rows of the crop instead of normal size tyres

to prevent trampling of plants under the tyres. The size of the sweeps range

from 4” to 6”. Its field capacity is 4 to 5 ha/day.

A 8 row tractor operated inter - culture implement used for weeding in groundnut

crop was demonstrated.

Its frame is provided with 8 tynes each tyne attached with T or V - shape sweeps

to work in between 30 cm row spacing of the crop without any plant damage. Two

small width pneumatic tyres of 8.3 X 28” size need to be fitted to the rear axle

of the tractor to run in between rows of the crop instead of normal size tyres

to prevent trampling of plants under the tyres. The size of the sweeps range

from 4” to 6”. Its field capacity is 4 to 5 ha/day.

4. Groundnut fresh pod thresher:

It is suitable for stripping of groundnut pods from harvested crop and consists

of a wire spike type cylinder powered with 0.25 hp electric motor. Stripping is

done by holding the portion of a bunch manually over spiked cylinder. Three

persons can work at a time. It is also provided with a blower and sieve for

separation of pods from plant stalk, leaves etc. it saves 40% labour, 50%

operating time and 30% cost of operation and it also results in 4% reduction in

losses compared to conventional method of stripping. It was developed by MYRADA,

KVK, Tamil Nadu. Output capacity is 120 kg/ha with 100% stripping efficiency and

98% cleaning efficiency.

It is suitable for stripping of groundnut pods from harvested crop and consists

of a wire spike type cylinder powered with 0.25 hp electric motor. Stripping is

done by holding the portion of a bunch manually over spiked cylinder. Three

persons can work at a time. It is also provided with a blower and sieve for

separation of pods from plant stalk, leaves etc. it saves 40% labour, 50%

operating time and 30% cost of operation and it also results in 4% reduction in

losses compared to conventional method of stripping. It was developed by MYRADA,

KVK, Tamil Nadu. Output capacity is 120 kg/ha with 100% stripping efficiency and

98% cleaning efficiency.

OUTPUT:

The productivity of the groundnut has been increased due to uniform spacing between plant to plant and row to row and depth of planting was maintained after intervention of KVK. The net income also increased due to the reduction in cost of cultivation which resulted in the increased cost benefit ratio. There was 87.50 percent of time saving and 37.50 percent cost saving while adopting Groundnut seed drill for sowing.

| S.No | Particulars | Yield (q/ha) | Gross Income | Net Income | B:C Ratio |

|---|---|---|---|---|---|

| 1 | Before Intervention | 12.2 | 63,203 | 22,840 | 1.57 |

| 2 | After Intervention | 14.7 | 78,550 | 40,202 | 2.05 |

OUTCOME:

From the Front-Line Demonstrations conducted during the 2019-20 it was found that adoption of Farm mechanization in groundnut cultivation significantly reduced the scarcity of labour. This technology was well received by the farmers due its effective nature. The farmer from the other blocks of Krishnagiri has also been made aware of the performance of farm machineries particularly the Tractor drawn seed sowing machine. Prior to this technology, the only option available with the farmer was to indigenous plough and human power. Mr. Krishnan, progressive farmers bought one tractor drawn seed sowing machine for his farmers group. When he started to use the machine for sowing the depth of planting and population was maintained which could increase his yield.

IMPACT:

KVK play a vital role in transfer of technology. Any activity can be hastened up

through the active participation and encouragement of the members of the society.

Our FLD farmers have inclination towards interdependence which strengthens the

co-operative spirit among the group members. Hence, the FLD farmers have look

forward for formation of fraternities, which helps in improving the positive

attitude towards innovation and its adoption. The farm machinery in groundnut can be

disseminated effectively among the group members. Due to the continuous effort taken

by KVK this technology reached to wider areas. Different extension activities like

Method demonstration, Field demonstration, field visits, and publishing extension

literatures were done. The adoption percentage is about 78 percentages now from a

meager value of 5 percentages.

Overall, the farm mechanization was found to be very sparse in each operation and

there is an ample scope for improving the farm mechanization status in groundnut

cultivation. The ultimate goal is to bring out seed to seed farm mechanization so as

to enable groundnut cultivation more lucrative.

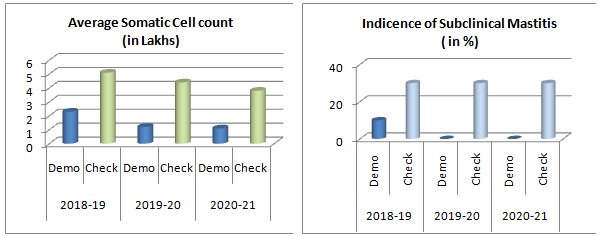

Demonstration of Mastiguard with Clean milk production practices has increased

average Milk yield by 6% and 10.17% in 2018-19 and 2019-20. The somatic cell

count were higher in farmers practice (5.1 lakhs during 2018-19 and 4.4 lakhs

during 2019-20) when compared with demonstration (2.3 lakhs during 2018-19 and

1.2 lakhs during 2019-20). Incidence of Sub-Clinical Mastitis was lower (10%

during 2018-19) or no incidence during 2019-20, when compared to farmer’s

practice (30 % during 2018-19 & 2019-20)

Demonstration of Mastiguard with Clean milk production practices has increased

average Milk yield by 6% and 10.17% in 2018-19 and 2019-20. The somatic cell

count were higher in farmers practice (5.1 lakhs during 2018-19 and 4.4 lakhs

during 2019-20) when compared with demonstration (2.3 lakhs during 2018-19 and

1.2 lakhs during 2019-20). Incidence of Sub-Clinical Mastitis was lower (10%

during 2018-19) or no incidence during 2019-20, when compared to farmer’s

practice (30 % during 2018-19 & 2019-20)

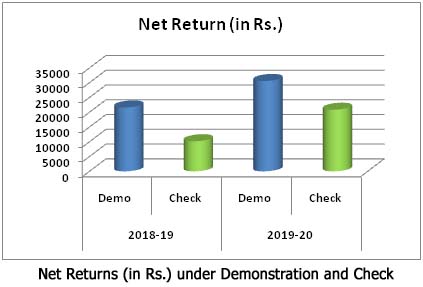

The Front-line demonstrations results showed that the highest yield was recorded

in adoption of Ragi variety CO15 variety (11.80 qtl/ha) followed by farmers

practice. The net return was highest in Ragi CO15 demonstrated field (Rs.

18,040)than compared to the farmers practice (Rs. 10,596). Yield increase

percentage was 16.62 in Ragi CO 15 compare to local variety.

The Front-line demonstrations results showed that the highest yield was recorded

in adoption of Ragi variety CO15 variety (11.80 qtl/ha) followed by farmers

practice. The net return was highest in Ragi CO15 demonstrated field (Rs.

18,040)than compared to the farmers practice (Rs. 10,596). Yield increase

percentage was 16.62 in Ragi CO 15 compare to local variety.

Our KVK conducted PRA at Periyamuthur village of Kaveripatinam block and the

surrounding paddy areas during 2007. In this block farmers were cultivating

paddy in around 450 ha. As soon as the water is released from the reservoir, the

paddy cultivation starts simultaneously in all the areas which results in acute

labour shortage for various operations. As the result of PRA conducted most of

the farmers cultivating paddy faces labour shortage. So, our KVK conducted a OFT

on Paddy Transplanter in Krishnagiri district to overcome the problem.

Our KVK conducted PRA at Periyamuthur village of Kaveripatinam block and the

surrounding paddy areas during 2007. In this block farmers were cultivating

paddy in around 450 ha. As soon as the water is released from the reservoir, the

paddy cultivation starts simultaneously in all the areas which results in acute

labour shortage for various operations. As the result of PRA conducted most of

the farmers cultivating paddy faces labour shortage. So, our KVK conducted a OFT

on Paddy Transplanter in Krishnagiri district to overcome the problem.

The training on post harvest management, harvesting, handling, grading and

packaging, storage and value addition in horticultural crops. This programme was

conducted in the month of April 2009. It was 15 days programme and 11 youth, SHG

women of Hosur participated in the training. Technical skills on processsing and

value addition were imparted through practical demonstration, training and

exposure visit.

The training on post harvest management, harvesting, handling, grading and

packaging, storage and value addition in horticultural crops. This programme was

conducted in the month of April 2009. It was 15 days programme and 11 youth, SHG

women of Hosur participated in the training. Technical skills on processsing and

value addition were imparted through practical demonstration, training and

exposure visit.